Laboratory high-intensity magnetic separator for battery recycling research

A European mining and technology university has purchased a laboratory-scale Bench Induced Roll Magnetic Separator (BIRS) for use in research projects including the recycling of lithium-ion batteries. The BIRS generates high-intensity magnetic fields up to 2 Tesla (20 000 Gauss), enabling the separation of weakly magnetic particles.

The Induced Roll Magnetic Separator (IRS) uses electromagnetically generated high intensity magnetic fields to separate small weakly and paramagnetic particles from non-magnetic materials with a particle size range between - 2 mm to 45 µm. The IRS comprises of an electro-magnetically induced steel roll positioned between a bridge bar and pole piece. The peak magnetic field generated on the production-scale induced roll is 2.2 Tesla (22 000 Gauss).

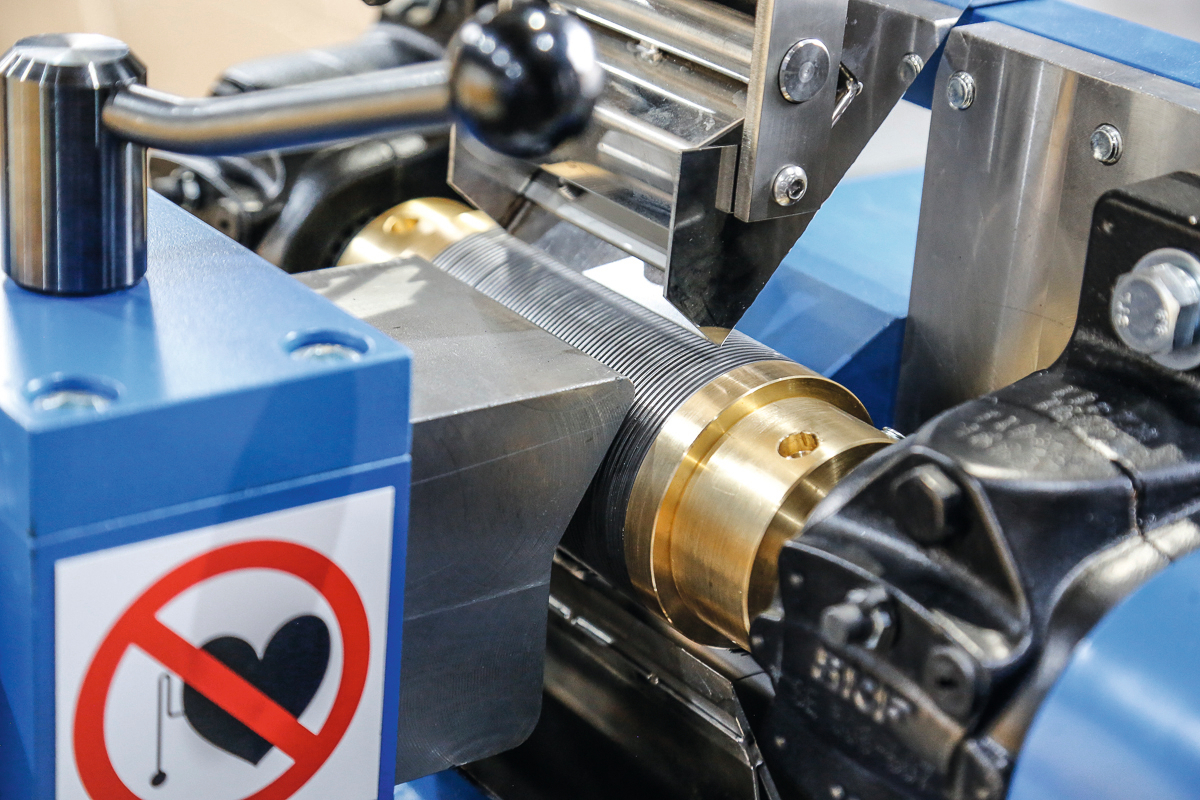

Bunting‘s Laboratory-Scale Bench Induced Roll Magnetic Separator (BIRS)

Bunting‘s Laboratory-Scale Bench Induced Roll Magnetic Separator (BIRS)

© Bunting

The IRS is widely regarded as one of the most robust, versatile and adjustable dry high-intensity magnetic separators. The intensity of the magnetic field enables the separation of weakly magnetic materials and minerals, leading to the wide use of the IRS in the ceramics and minerals industries.

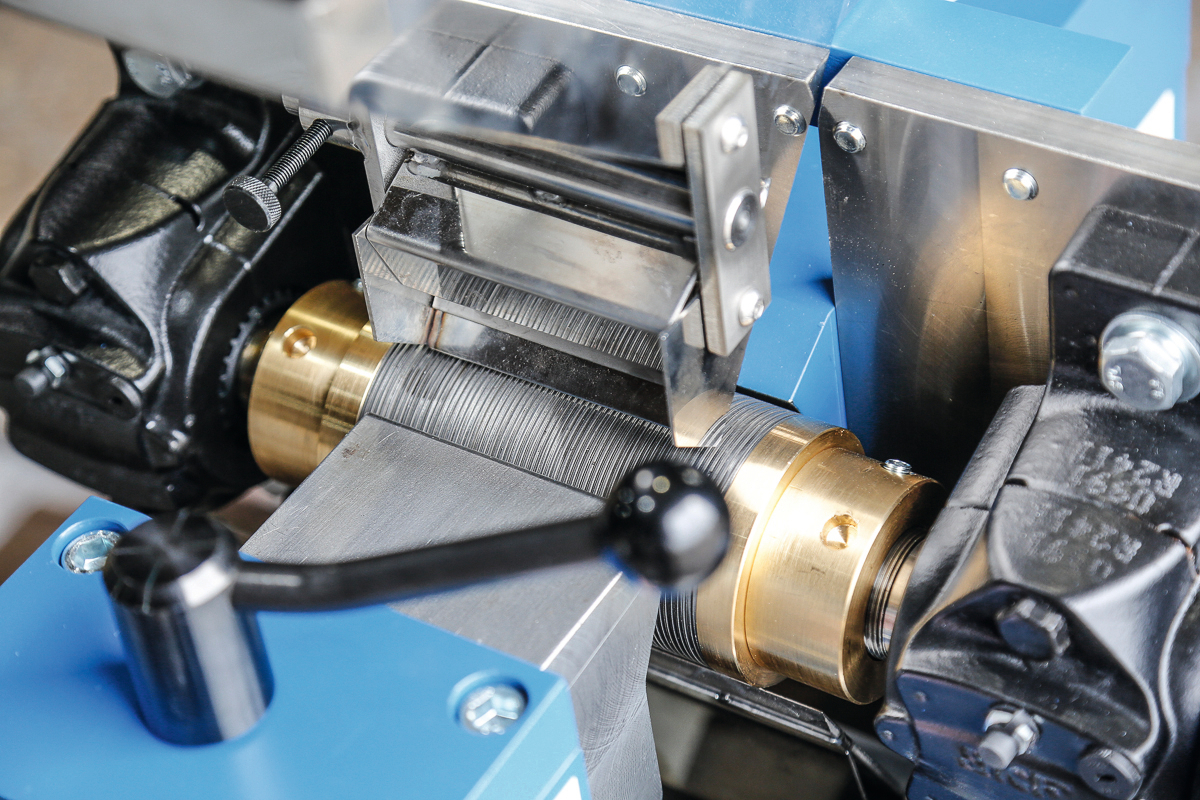

The adjustability makes the bench version of the IRS ideal for research projects. The three key adjustable features are to vary the magnetic field strength; adjust the roll speed, which balances the centrifugal force against magnetic attraction; and splitter plate settings to create three fractions (magnetics, middlings, and non-magnetics). Regulating the power to the electromagnetic coils varies the magnetic field strength up to a peak of 2 Tesla. This allows the preferential separation of particles with different magnetic susceptibilities. Varying the speed of the magnetically induced roll changes the centrifugal forces applied. The final variant is the gap between the induced magnetic roll and the pole, with a smaller gap (down to a minimum of 2 mm) enabling a higher magnetic intensity. The gap is dependent on the particle size range of the material.

The high-intensity magnetic roll of the BIRS

The high-intensity magnetic roll of the BIRS

© Bunting

Unlike other high-intensity magnetic separators generating magnetic fields using permanent magnets, the electromagnetic Induced Roll Separator has the capacity to process hot material feeds (up to between 80° C and 100° C) without any degradation of magnetic intensity.

The university research team is assessing physical separation techniques, both dry and wet, to recycle problematic waste such as lithium-ion batteries. Within the scope for dry separation, the team required the BIRS to handle particles between 0.1 and 2 mm, with a focus on separating the finer grains.

The laboratory-scale Induced Roll Magnetic Separator (BIRS) forms part of a range of equipment designed specifically for research and laboratories for both wet and dry processes.